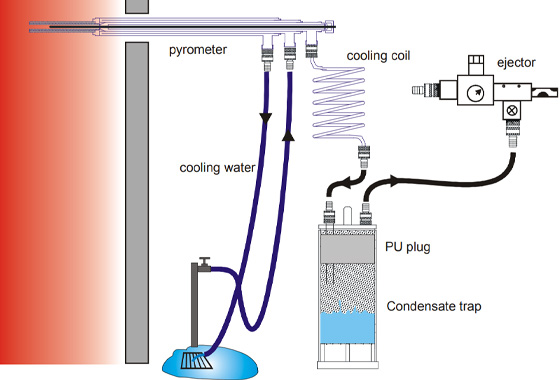

Suction Pyrometry

True Gas Temperature measurement using a Suction Pyrometer. This is the measurement of the hot gases generated as the result of combustion processes. Conventional thermocouples do not give accurate results because of interference from the radiated heat of the surroundings and open flames.

Suction Pyrometers

When a conventional thermocouple is used, the amount of interference is a function of the relative values of the radiant heat transfer coefficient of the surroundings and the convective heat transfer coefficient of the gas. When a standard thermocouple is used in a cold furnace, the resulting error can be several hundred degrees. Suction pyrometers have been developed in order to reduce this error.

The suction pyrometer consists of a sheathed thermocouple (sheathed against chemical attack) located inside a radiation shield at the tip of a suction pipe. The combustion gases are sucked through the shield and over the thermocouple at high velocity by aspirating equipment. The efficiency of this aspirating thermocouple is a function of the quality of the radiation shield and of the suction flow rate. If, for example, a suction pyrometer has a 100°C error without suction and a 10°C error when the suction flow is on, it is said to have an efficiency of 90%. The suction pyrometer probe is usually made of stainless steel and is water-cooled. These probes are designed for high gas velocities. At such velocities the radiation shields usually produce better than 90% pyrometer efficiencies.

Energy Plant Solutions are able to measure the likes of boiler reversal chambers, furnaces and hot gas ducts with our Suction Pyrometer. This enables true gas temperatures to be established to maximise outputs and protect your plant from being overfired which could cause damage to your plant.