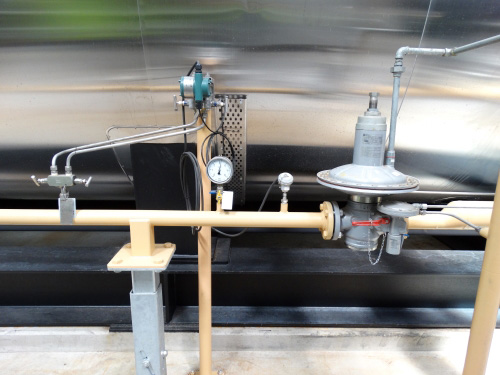

Gas Fitting

Energy Plant Solutions are able to design, supply, install and service gas control equipment, this includes pressure reducing valves, earthquake seismic gas valves and gas regulators.

A seismic gas shut off valve is an inexpensive one-time measure to increase the safety and wellbeing of your business. Energy Plant Solutions installs seismic gas shut off valves to stop the flow of gas automatically when significant earthquake activity occurs. When activated, the valve will no longer allow gas to flow through the line into your industrial installation, preventing the potential for gas explosions and fire.

The Gas (Safety and Measurement) Regulations 2010 require gas work to be carried out safely, and for the completed work to be safe. Gas installation and certain other gasfitting work must be certified by a certifying gasfitter or other person authorised under the Plumbers Gasfitters and Drainlayers Act 2006. There is a general obligation on everyone who designs, constructs, maintains, uses or manages a gas distribution system to ensure the distribution system is safe. Owners and operators of major gas supply systems are required to implement and maintain a Safety Management System (SMS).

Requirements of an SMS (Safety Management System)

A Safety Management System ensures so far as reasonably practicable, the gas supply system does not pose significant risk of serious harm to a person or significant damage to property. Owners and operators of gas supply systems that supply, or are intended to supply, annual consumption greater than 10 TJ of gas per year, are required to implement and maintain an SMS.

SMS’s create an environment where all aspects of the design, construction and operation of a gas distribution system are subject to third party audit and certification. This allows the owner or operator of a distribution system to fulfil their legal obligations for safety in a rigorous manner while at the same time allowing a certain amount of flexibility in their implementation. A gas supply system is the distribution system plus any related installations, appliances and fittings that form part of a system for conveying gas to consumers (section 46A of the Gas Act).

Each SMS must be fully documented and provide for the following:

- The systematic identification of hazards.

- The assessment of hazards.

- The steps to be taken to eliminate, isolate, or minimise hazards and to mitigate risks from those hazards.

- Assessment of the effectiveness of this risk management.

- Investigation of accidents.

- Enhancement of safety performance throughout the system including performance measurement.

- An audit programme.

Every SMS must be regularly audited to confirm it is being implemented and maintained in compliance with these requirements. Operators of SMS’s are required to provide WorkSafe with a statutory declaration at least once every five years to confirm the operator has a current audit certificate. The first such statutory declaration must be made and sent to WorkSafe within six months of the first audit of the SMS. Auditors are required to cancel the audit certificate for an SMS if the requirements for an SMS are not met, or if WorkSafe directs cancellation on the grounds that the SMS is not being implemented. Owners or operators of other distribution systems that are not gas supply systems may opt to have an SMS in order to meet their safety obligations.